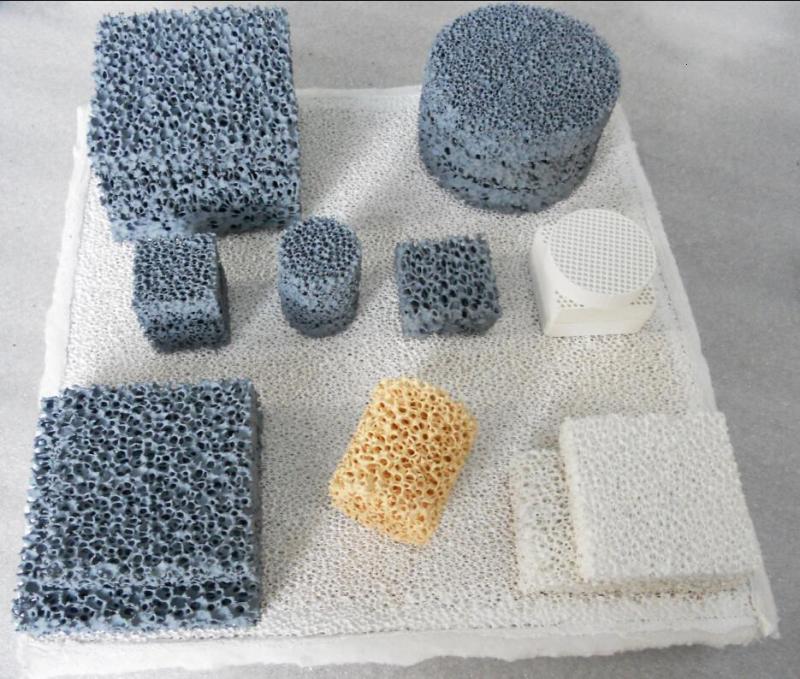

ceramic foam filter for foundry molten metal filtration

Paglalarawan ng produkto

Silicon carbide ceramic foam filters are mainly designed to improve the quality of iron castings. The filter can effectively remove non-metallic inclusions including slag and dross from the molten metal stream.Additionally, they aid in reducing turbulence in the gating system.SIC ceramic foam filter's outstanding thermal shock resistance and high strength properties were developed for superior performance in extreme iron or aluminum and copper based alloy foundry applications.

MODEL NAME: SIC-CFF

DESCRIPTION: Silicon carbide ceramic foam filter

APPLICATION: For the filtration of molten iron and non-ferrous castings

PRODUCT FEATURES:

-Precise sizes control during filter media sponge cutting to final sinter.

-High strength with enough slurry and free from loose debris,no break and no filter slag.

-Branded main raw material to ensure stable quality.

-Good porosity and free from block during pouring molten metal.

-Mature sintering technology to ensure high refractory and good thermal shock resistance.

PHYSICAL PROPERTY:

Main material SIC, Al2O3, SIO2

Aplied Temperature ≤1500℃

Color Dark gray

Hole density 10/15/20/25/30PPI(PPI=pores per inch)

Porosity(%) 78-90

Compressive Strength(MPa) ≥1.0 (Room temperature)

Bulk Density(g/cm3) 0.45-0.60

Thermal shock resistance ≥2times/1100℃-Room temperature

CHEMICAL COMPOSITION:

Component CAS NO. % By Weight

Silicon Carbide (SiC) 409-21-2 >60

Aluminum Oxide (Al2O3 ) 1344-28-1 30-35

Amorphous Silica (SiO2 ) 7631-86-9