Steam Heating Pad (Rubber Hose Z/U Type)

ఉత్పత్తి వివరణ

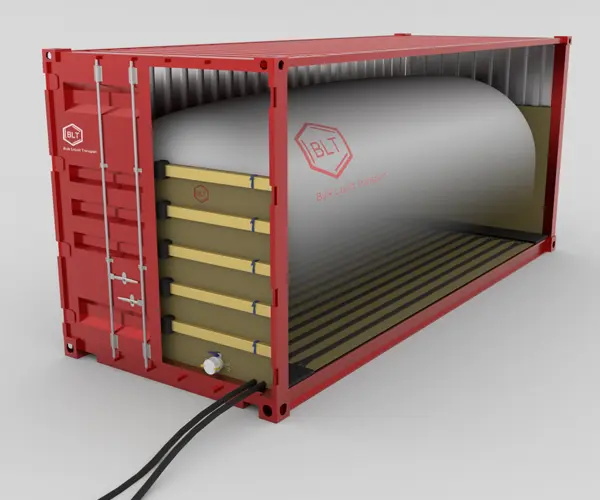

Steam Heating Pad (Rubber Hose Z/U Type)

Heating the liquid inside the bag is achieved by channeling steam into the rubber tubes

Materials: EPDM rubber pipe, galvanized iron pipe

Perfect for products that solidify at low temperatures and for unloading sites equipped with steam systems where condensate discharge is prohibited.

Specifications of Steam Heating Pad for Water Tank ( Rubber Hose Z/ U Type)

Materials EPDM rubber pipe, galvanized iron pipe

Size 5600mmx2250mm

Applicable Goods products easy to solidify at low temperatures

Packing Dimension 2310mmx500mmx290mm (Lx Wx H)

Features of Steam Heating Pad( Rubber Hose Z/ U Type)

Efficient Heating

The rubber tube steam heating pad efficiently and evenly conducts heat, quickly raising the temperature of the liquid inside the bag.

Durable Materials

Constructed from EPDM rubber tubes and galvanized iron tubes, these flexitank heating pad offer excellent corrosion resistance, making them suitable for a variety of complex environments.

Convenient Installation

Designed for easy transport and installation, these pads save both time and labor costs.

How to Choose Flexitank Heating Pads?

Name Rubber Tube Steam Heating Pad Iron Tube Steam Heating Pad Electric Heating Pad

Specification (32 tubes/48 tubes) (Standard/Extended) (220V/380V)

Material High-temperature EPDM rubber tube/Galvanized iron tube Galvanized tube/High-temperature rubber tube/Thermal insulation felt Resistance wire/Aluminum foil paper/Thermal insulation felt

Size Length 5.6m * Width 2.25m (Size tolerance 5cm) Standard: Length 4.7m * Width 2.1m (Length 5.5m * Width 1.2m) * 2

Extended: Length 5.5m * Width 2.1m

Applicable Products Low-temperature coagulated products Low-temperature coagulated products Low-temperature coagulated products

Products requiring specific temperature

On-site Requirements Steam system Steam system Circuit system

Condensate Discharge None Yes None

Qingdao BLT Flexitank Solution Co., Ltd., established in 2007, specializes in high-quality flexitanks. The flexitank milk company aims to make liquid transportation safer, more economical, and convenient, with production plants covering nearly 200,000 square meters. Equipped with advanced testing instruments, BLT enforces strict quality control throughout the supply chain. With over 50 branches in 150 cities and 500 international ports, BLT provides a 360° service system and 24-hour global after-sales support, ensuring exceptional customer service and satisfaction.