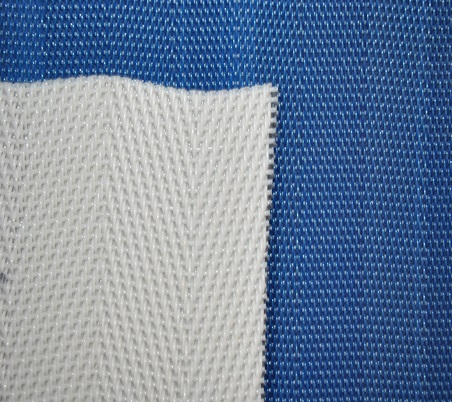

Polyester Sludge Dehydration Fabrics(Press-Filter Fabric)

Produkto aprašymas

Polyester Sludge Dehydration Fabrics(Press-Filter Fabric)

Sludge Dehydration Fabrics(Press-Filter Fabric)

Introduction

Sludge Dehydration Fabrics is also called Press-Filter Fabrics which is mainly used for sludge dehydration, paper pulp and juice squeeze, Mine smelting, mine tailing disposal and other pressure filtration industries. They have the characteristics of good water permeability and non-revealed sludge, acid-resisting and alkali-resisting. Because of their designing structure, The sludge can be peel off easily from the filter cake, So the screen are easily cleaned and have a long working time. Mainly matching with belt type filter press, Vacuum rubber belt filter and horizontal vacuum belt filter.

Characteristics and Advantages

Good water permeability

Good air permeability

Acid- resistance, alkali- resistance, temperature resistant

Heat resistance under 180 degrees

Waterproof polyester filter mesh for sludge dehydration with smooth surface mesh, high strength, excellent conduct electricity and saving energy;

Applications

Polyester synthetic filter mesh screen for dewatering is mainly used for sludge treatment in food processing industry and sewage treatment factories,such as paper making,printing and dying, washer wrinker fabric factory etc. Industries listed below:

- Filtration

- Sludge dewatering

- Industrial draining usage

- Food cleaning and processing

Model of Fabrics Wire Diameter(mm) Density(wire/cm) Strength(N/cm) Air Permeabilitym3/m2h

Warp Weft Warp Weft Area of the surface

16903 0.7 0.9 16 5.33 ≥2200 7894±500

22903 0.5 0.9 22 5.33 ≥2000 6800±500

26808 0.5 0.8 27 8.5 ≥2100 5120±500

15905 0.9 0.9 17 4.8 ≥4500 6741±500

151105 0.9 1.1 16 4.8 ≥5000 6749±500

121104 0.9 1.1 12 3.8 ≥3600 8610±500

Specification List:

Model Wire diameter

mm Density

Root/10cm Air permeability

m3/m2h Net weight

g/㎡ Strength

kg/cm Used in

Warp Weft Warp Weft

WNW14803 0.7 0.8 142 47-60 3900- 8500 1400 240 Sludge, Squeeze juice

WNW16803 0.7 0.8 156 46-50 6000 1400 265 Sludge, Squeeze juice

WNW16904 0.75 0.9 156 47 8000 1800 280 Iron and steel industry sludge dewatering and

Life sludge dewatering

WNW121054 0.9 1.05 120 42 8000 1650 340 Iron and steel industry sludge dewatering

WNW22903 0.5 0.9 220 50-55 9000- 10000 1200 200 Life sludge dewatering

WNW20703 0.5 0.7 200 70 10000 1000 185 Life sludge dewatering and

Chemical sludge dewatering

GW24504 0.5 0.5 240 130-140 8500- 10000 1180 220 Paper dry network and

Paper sludge dewatering

WNW08903 0.9 0.9 78 50 8500 1430 210 Industrial sludge dewatering

WNW16704 0.7 0.7 160 90 12000 1350 265 Building materials industries

WNW26908 0.5 0.9 26.4 69-75 5000- 5500 1364 240 Viscosity of the large Sludge

CXW12 Mesh 0.75 0.8 47 48 650 94 Paper pulp washing