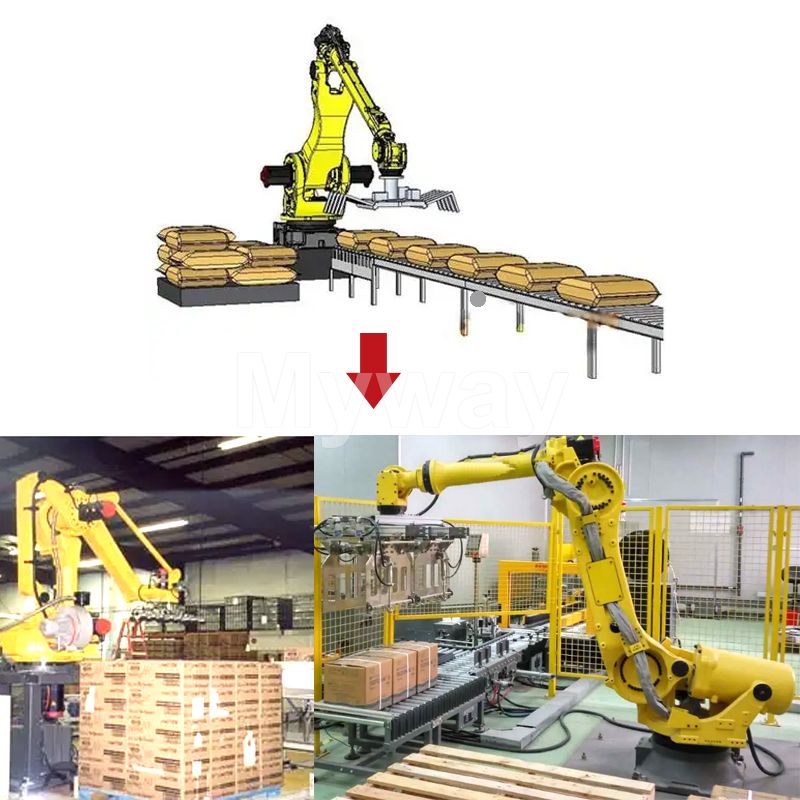

automatic palletizer robot

제품 설명

automatic palletizer robot

Introducing the Automatic Palletizer Robot - Revolutionizing Warehouse Efficiency

The Automatic Palletizer Robot is a cutting-edge technological solution designed to streamline the palletizing process in warehouses and distribution centers. With its advanced features and capabilities, this robot offers immense efficiency, accuracy, and productivity, transforming traditional palletizing methods.

With the increasing demands of the modern era, the need for faster and smarter solutions in logistics and material handling is paramount. The Automatic Palletizer Robot emerges as the ideal solution, leveraging the power of automation to optimize warehouse operations. This state-of-the-art robot is equipped with various sensors, high-precision algorithms, and intelligent control systems to handle palletizing tasks with unparalleled precision.

One of the key advantages of the Automatic Palletizer Robot is its ability to handle a wide range of products and packaging formats. From cartons, boxes, sacks, drums, to trays, this robot can effortlessly accommodate a vast array of package types, sizes, and weights. Its flexible grippers and adjustable palletizing patterns enable it to adapt to different products and conveyor systems, making it suitable for diverse industries such as food and beverage, pharmaceuticals, manufacturing, and more.

The intelligent software of the Automatic Palletizer Robot is designed to optimize palletizing layouts, maximize load stability, and minimize wasted space. The robot meticulously analyzes the products' dimensions and weight, automatically generates optimized pallet patterns, and ensures secure stacking to minimize the risk of damage during transportation and warehousing. This not only enhances overall product integrity but also optimizes space utilization, reducing the number of pallets required and ultimately lowering shipping costs.

The real-time monitoring and control system incorporated in the Automatic Palletizer Robot enables warehouse operators to efficiently manage multiple palletizing processes simultaneously. With a user-friendly interface, operators can easily configure product specifications, pallet layouts, and stacking patterns, making it a highly customizable and adaptable solution.

In addition to its exceptional accuracy and speed, the Automatic Palletizer Robot also ensures superior workplace safety. By automating the palletizing process, the risk of manual handling injuries is greatly reduced. The robot can handle heavy loads effortlessly while adhering to stringent safety regulations. Its collision detection sensors and enhanced control system enable the robot to smoothly navigate through the warehouse and work in close proximity to human operators without compromising safety.

Furthermore, the Automatic Palletizer Robot seamlessly integrates into existing warehouse automation systems. It can receive and process data from various sources, such as conveyor belts, barcodes, or enterprise resource planning (ERP) systems, ensuring seamless flow of information and minimizing the need for manual intervention. This integration improves overall operational efficiency, reduces human errors, and enables end-to-end automation of the palletizing process.

The Automatic Palletizer Robot is not only an investment in efficiency but also sustainability. By optimizing pallet configurations, it contributes to reducing overall packaging material consumption and waste generation. It also helps in reducing carbon emissions through efficient warehouse operations, leading to a greener, more eco-friendly supply chain.

In conclusion, the Automatic Palletizer Robot revolutionizes warehouse efficiency with its advanced automation capabilities, flexibility, and precision. By automating the palletizing process, it enables businesses to achieve higher productivity, cost savings, and improved safety. With its ability to handle various product types and packaging formats, this