Eddy Current Inspection is inconvenient to be used in complex-shaped components

Описание товара

Eddy Current Inspection is inconvenient to be used in complex-shaped components

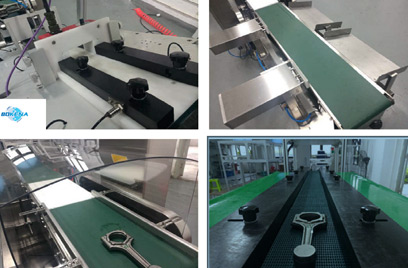

Eddy current flaw detection is a defect of an alternating current electromagnetic coil in the metal plane layer, which is not convenient to use in complex shape components. In thermal power plants, it is mainly used to detect condenser tubes, turbine blades, turbine rotor central holes, and welds. Principle When AC is fed into the coil, if the voltage and frequency used remain unchanged, the current through the coil will also remain unchanged. If a metal tube is placed in the coil, the circumferential current, or eddy current, is induced on the surface of the tube. The direction of the eddy current magnetic field is opposite to the magnetization direction of the applied current, so it will offset part of the applied current so that the impedance of the coil and the magnitude and phase of the current will change. The impedance of the coil is affected by the change of diameter, thickness, conductivity and permeability of the tube and the existence of defects. If other factors remain unchanged, only the signal of impedance caused by a defect is taken out, amplified and tested by instrument, the purpose of flaw detection can be achieved. The eddy current signal can not only give the size of defects but also determine the position t (depth) of defects according to the phase of eddy current lagging behind the surface eddy current. In eddy current testing, the detection coil can be used according to the phase of the detection coil and the components to be inspected. The interrelationship can be divided into three categories: through a coil, through a coil and inside the coil. If it is necessary to insert the workpiece and pass the coil detection, the through the coil is used. When inspecting pipe fittings, sometimes coils must be placed inside the pipe to inspect, and the eddy current inspection equipment adopts the through the coil. When the T-type (point) coil is used, the coil is placed on the surface of the workpiece to be inspected for inspection. This kind of coil is small in size, usually has a magnetic core inside the coil. It has high sensitivity and is easy to carry. It is suitable for surface crack inspection of large components, plates and strips. According to the way of using the detection coil, it can be divided into three types: absolute coil, standard comparison coil and self-comparison coil. Only one detection coil is called the absolute coil type, and two detection coils are connected into differential form, which is called the standard comparison coil type. Two coils are placed in different parts of the same component to be tested. They are called self-comparison coils. They are special cases of standard comparison coils. The basic circuit consists of an oscillator, output circuit of detection coil signal, amplifier, signal processor, display and power supply.

The difference between eddy current testing and ultrasonic testing:

Ultrasound flaw detection is a method to inspect the defect of a part by means of the reflection characteristics of the interface edge when the ultrasonic energy penetrates into the depth of the metal material and one section enters another section. When the ultrasonic beam passes from the surface of the part to the inside of the metal from the probe, the reflected waves will occur separately when the defect and the bottom of the part are encountered. Pulse waveforms are formed on the fluorescent screen, and the position and size of defects are judged according to these pulse waveforms.