Fabric Conveyor Belt

Περιγραφή του προϊόντος

Fabric Conveyor Belt

Rentone Belt Co., Ltd. is a leading and trusted conveyor belt manufacturer for more than ten years. We are committed to supplying top-notch quality fabric conveyor belts with attractive pricing for customers across the globe. Our fabric conveyor belts boast excellent features of superior impact and wear resistance, high strength, excellent flexibility and durability, and long working life. They are mainly used in the mining, quarries, power plant, steel plants, foundries, agriculture, manufacturing, and cement industries. Trust Rentone Belt that provides you with a reliable and innovative solution to make material conveying safe, efficient, and eco-friendly.

Types of Fabric Conveyor Belt

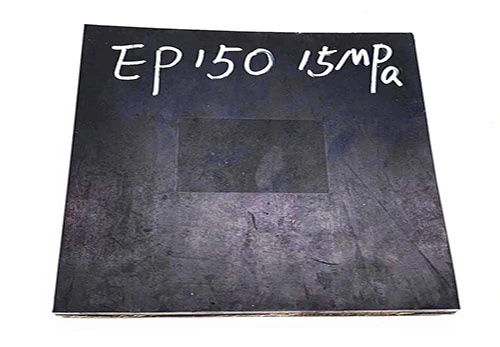

EP Conveyor Belt

NN Conveyor Belt

Heat Resistant Conveyor Belt

Fire Resistant Conveyor Belt

Oil Resistant Conveyor Belt

Acid-alkali Resistant Conveyor Belt

Structure of Fabric Conveyor Belt

Top Cover: Designed to safeguard the carcass from various service conditions. It provides robust protection against damaging elements such as oil, heat, and abrasion, ensuring the longevity and durability of the belt in harsh working environments.

Skim rubber: Positioned between the plies, the skim rubber is specially compounded to offer superior adhesion. This layer plays a critical role in preventing ply separation, thereby maintaining the structural integrity of the belt during operation.

Textile fabric (EP,NN, CC): These materials are chosen for their exceptionally low stretch characteristics and excellent troughability, which enhance the belt's performance and adaptability to various conveyor configurations.

Bottom Cover: Designed with a focus on abrasion resistance and flexibility. It provides a durable wearing surface that withstands the continuous contact with pulleys and idlers, thereby extending the operational life of the belt.

Features of Fabric Conveyor Belt

1. Enhanced performance: Offering high tensile strength, durability, low stretch characteristics, and flexibility, these features ensure reliable and efficient operation in demanding conditions, making the fabric conveyor belts suitable for handling heavy loads and high-stress environments.

2. Various cover grades: Abrasion-resistant, heat-resistant, oil and chemical-resistant, and flame-resistant covers enhance the adaptability of fabric conveyor belts. These specialized covers provide additional protection and extend the belt's lifespan, catering to specific industrial requirements.

3. Versatility: Fabric conveyor belts offer a wide range of applications across different industries, ease of installation and maintenance, and compatibility with various troughing configurations. Customizable designs allow for tailored solutions to meet specific operational needs, making them a practical choice for diverse applications.

4. Environmental friendliness: With options for biodegradable and recyclable materials, energy-efficient operation, and eco-friendly manufacturing processes, these belts contribute to sustainability efforts and reduce environmental impact, aligning with modern industry standards and practices.

The Role of Textile/Fibers in Fabric Conveyor Belting

Textiles or fibers serve an important role in conveyor belting system. Common textiles used include natural cotton and wool, and man-made synthetic nylon and polyester. Different types of textiles serve different purposes. Cotton and wool boast same features of moderate strength, high elongation, low cut and abrasion resistance, moderate temperature resistance, and low mildew resistance. Both nylon and polyester share similar characteristics like high strength, high elasticity, moderate elongation, high cut and abrasion resistance, and high mildew resistance, except that polyester possesses low-temperature resistance properties.