Laser Cutting

Ապրանքի նկարագրությունը

Laser Cutting

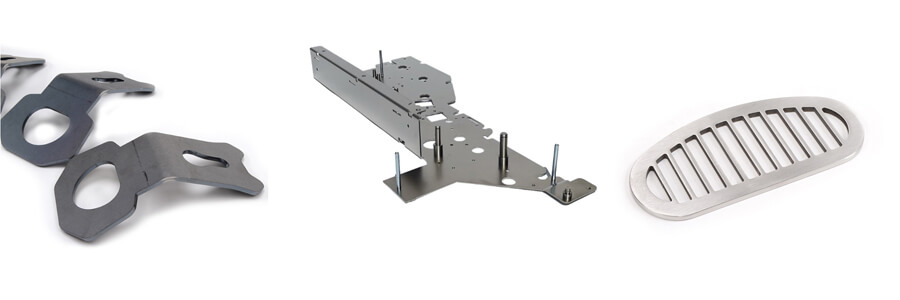

Sheet metal laser cutting service has obvious advantage such as high precision, high speed and low cost compared with other traditional cutting method. Shanghai Yixing Technology provides professional custom laser cutting service for all industries. Thickest material can be 20mm for carbon steel and 14mm for stainless steel.

What Are CNC Laser Cutting Services of Yixing Technology?

Laser cutting is an efficient and economical cutting process. It is the use of a high density laser beam to irradiate a workpiece, causing the irradiated material to vaporize and melt, while using high-speed airflow to blow away the material, in order to cut the workpiece out. It leaves edges with high-quality surface finish. Industrial laser cutting machines are generally used to cut flat materials as well as structural and pipeline materials. Stainless steel laser cutting is a mainstream technology known for its accuracy, efficiency, and versatility. Shanghai Yixing Technology is also equipped with 3D laser cutting machine to meet customers'different needs.

Custom Laser Cutting Services Material

Laser cutting machine can cut metals, plastic, wood, leather and even cardboard. Below is the summary of the metal material we can cut. The material and its thickness choice is highly dependent on the machine parameters.

Material Grade

Aluminium 2024, 5052, 5754, 6061, 6063, 1060 et

Carbon Steel SPCC, HRS, SAPH440 etc

Stainless Steel 201, 301, 304, 316 etc

Cold or Hot Dip Galvanized Steel DC01+Z100, S220GD+Z100, DX51D+Z100, DC01+Z275, S220GD+Z275, DX51D+Z275 etc

ZINCALUME Steel DC01+AZ150

Advantages of Custom Laser Cutting Services in Shanghai Yixing Technology

In Shanghai Yixing Technology, we will use the most suitable laser cutting equipment like 3D laser cutting machine 1500W and flat laser cutting machine 2000W according to the material and design shape and also other external suppliers resource to fully meet customers' demands.

Advantages of Custom Laser Cutting Services in Shanghai Yixing Technology

We provide accurate and fast sheet metal fabrication services such as custom laser cutting services for all industries like automobile, agriculture, solar industry etc. There are hundreds of materials we can laser cut and we do not set minimum order QTY so as to relieve customers’ financial pressures. We are friendly to new start project with small quantities.

Advantages of Custom Laser Cutting Services in Shanghai Yixing Technology

We have professionally trained engineer who can fully control the beam intensity, thermal output, and duration during the laser cutting process. Therefore, our laser cutting process is highly reliable and helps to significantly avoid errors and reduce material waste.

FAQ of Laser Cutting

What is the thickest flat sheet you can laser cut?

We offer different thickness specifications for different laser cutting materials. The laser cutting equipment parameters will decide what thickness we can cut.

For aluminum laser cutting, the thickest flat sheet we can laser cut is around 10mm.

For stainless steel laser cutting, the thickest flat sheet we can laser cut is around 14mm.

For carbon steel laser cutting, the thickest flat sheet we can laser cut is around 20mm.

How long does it take to laser cut materials?

Laser cutting is one of the most efficient cutting method that can cut steel materials very fast. This ensures that various cutting projects will be completed very quickly while at the same time save material costs. With precise laser cutting machines in Shanghai Yixing Technology, we can provide faster lead times and reasonable pricing for customers.