Types And Characteristics Of Fasteners

Paglalarawan ng produkto

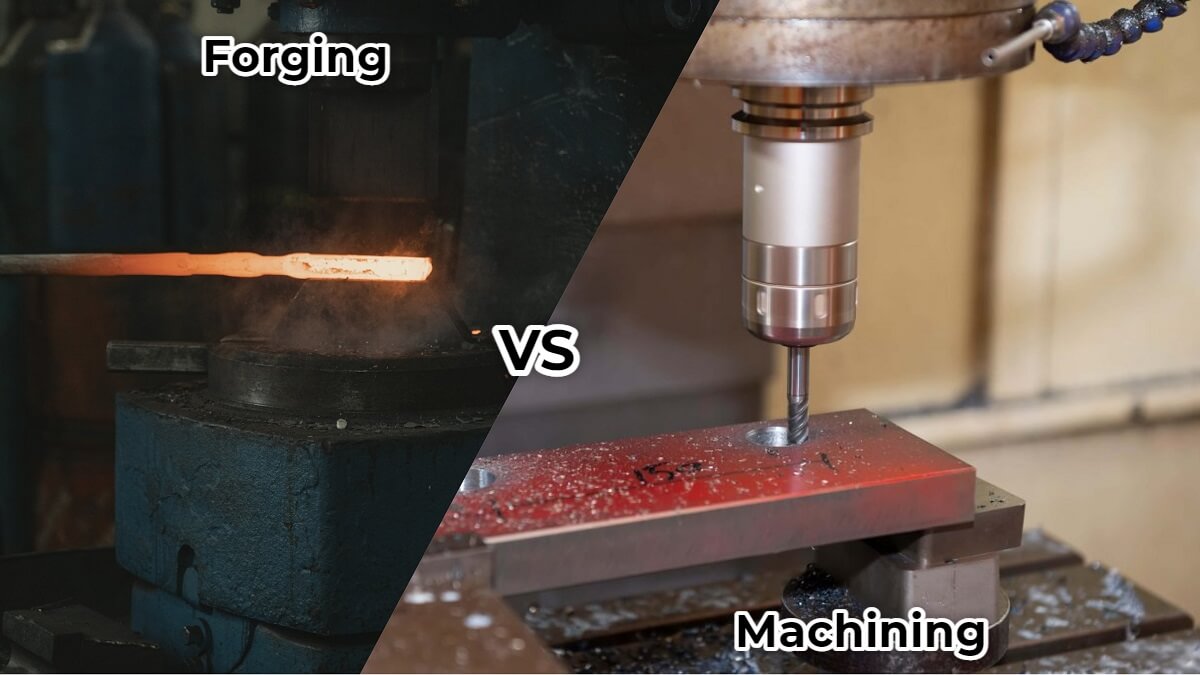

Forging vs Machining: Unveiling the Essence of Manufacturing Excellence

In the ever-evolving landscape of manufacturing, the decision between forging and machining becomes the linchpin determining the quality, efficiency, and cost-effectiveness of the end product. Navigating the complexities of these two processes requires a nuanced understanding of their intricacies, advantages, and applications.

Craftsmanship Unveiled

The Art of Forging

Forge ahead into the rich heritage of forging, a process rooted in the ancient art of shaping metals through controlled force. Beyond the superficial layer of its definition lies a profound method of enhancing material strength. When we talk about forging, we’re delving into a process that extends beyond the mere shaping of metal; it’s a transformative journey that refines the very essence of the material.

For instance, consider the intricacies of open-die forging, a method that imparts superior structural integrity by aligning grain flow, reducing porosity, and enhancing impact resistance. As the metal undergoes controlled deformation under immense pressure, its internal structure undergoes a metamorphosis, resulting in components with exceptional strength and durability.

Machining Marvels

Machining, on the other hand, emerges as a symphony of precision, a ballet of cutting and shaping that transforms raw materials into intricate components. Imagine a process where a computerized numerical control (CNC) machine meticulously carves out detailed designs with unmatched accuracy. It’s not merely a mechanical dance but a choreography of technology and skill, where every cut and turn is a testament to human ingenuity.

The beauty of machining lies in its adaptability to a myriad of materials, from metals to plastics, allowing for the creation of components with unparalleled precision. From aerospace parts requiring razor-sharp accuracy to medical implants demanding microscopic intricacy, machining stands as the go-to method for achieving exacting specifications.

Deciphering Process Disparities

Forging in Detail

To truly grasp the essence of forging, let’s explore the various techniques that fall under its expansive umbrella. Forging isn’t a one-size-fits-all approach; it’s a spectrum of methodologies tailored to specific applications.

Consider the precision of closed-die forging, a method where a piece of metal is placed in a die and shaped using compressive forces. The intricacies of closed-die forging extend beyond the initial impression, involving preform design, die materials, and temperature control. Delve into the world of isothermal forging, where temperature management plays a pivotal role in enhancing material flow, reducing die wear, and ultimately influencing the final product’s quality.

Machining Steps and Characteristics

The symphony of machining unfolds in a series of meticulously orchestrated steps. Imagine a CNC milling machine, where a cutting tool moves in multiple dimensions, crafting intricate patterns with mathematical precision. From the initial design phase to toolpath planning and execution, each step in machining is a meticulous dance of technology and craftsmanship.

Now, let’s shine a spotlight on Richconn’s turning services. Richconn, a leader in precision machining, excels in CNC turning services that redefine precision and efficiency. Their state-of-the-art CNC turning centers, equipped with advanced tooling and controls, ensure unparalleled accuracy in creating cylindrical components.

Richconn’s turning services encompass a wide array of materials, from traditional metals to advanced alloys, showcasing their adaptability to diverse industry needs. The meticulous attention to detail in tool selection, cutting speeds, and feed rates distinguishes Richconn’s turning services, making them a trusted partner for industries demanding the highest standards.