Description of breakout fiber optic cable

Апісанне тавару

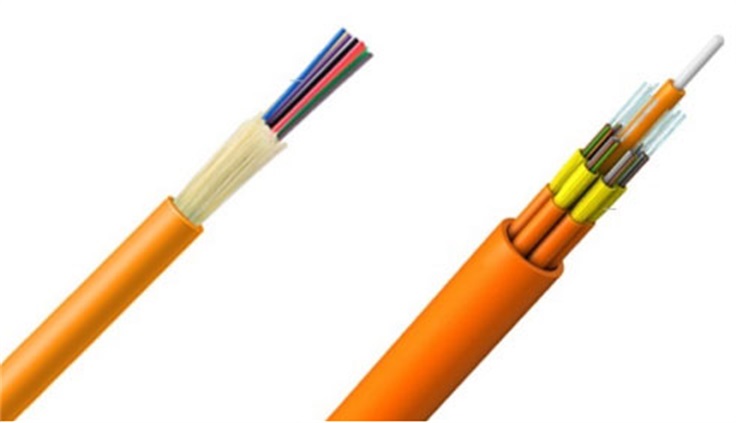

optical breakout cable also can be called as distribution fiber optical cable is designed for Indoor uses. There are two types of breakout fiber cables. One is inside with 2.0/3.0mm tight buffered cables. The fiber glass cores of this cable structure commonly can reach 48 cores. The other is inside with 0.9mm tight buffered around with Kevlar yarn as strengthen support.

Types of Breakout indoor optical cable

Indoor Breakout Fiber Optic Cable GJFJV 2-48 Cores 2.0mm 3.0mm Simplex FRP LSZH or PVC

Indoor Breakout Multi-core Fiber Optic Cable GJFJV 12 cores 0.6mm 0.9mm FRP PVC or LSZH

Indoor Distribution Fiber Optic Cable GJFJV 2-24 Cores Central Tube 0.9mm 0.6mm Aramid Yarn LSZH

Indoor/Outdoor Central Tube Distribution Fiber Drop Cable GYJFXTY 2-24 Cores G.657A2 Aramid Yarn PBT

Description of Breakout Fiber Optic Cable

12 core fiber optic cable also can be called as distribution fiber optic cable is designed for indoor uses. There are two type of fiber breakout optic cable. One is inside with 2.0/3.0mm tight buffered optical cables. The fiber cores of this fiber optic cable structure commonly can reach 48 cores. Another is inside with 0.9mm tight buffered and the fiber cores is 24-288 cores.

Both types of breakout fiber optic cable can be reinforced with aramid yarns to provide additional tensile strength and protect the fragile optical fibers inside. Aramid yarn is a key component of fiber optic breakout box, providing enhanced strength, protection and stability. Its high tensile strength and resistance to external factors make it an excellent choice for reinforcing fiber optic cables and ensuring the longevity and reliability of optical connections.

Outer Jacket Material Selection for Breakout Fiber Optic Cable

The outer jacket material of fiber optic cables plays a vital role in protecting and ensuring the performance of the optical cables. Here are some common types of outer jacket materials used in fiber optic cables:

PVC (Polyvinyl Chloride): PVC is a widely used material for the outer jacket of fiber optic cables. PVC jackets are generally cost-effective and have good flame retardant properties. However, they release toxic fumes when burned.

LSZH (Low Smoke Zero Halogen): LSZH optical cable are designed to minimize the release of smoke and toxic halogens when exposed to high heat or fire.

Anti-Fire (OFNR, OFNP): These designations refer to specific fire safety standards for fiber optic cables.

OFNR optical cables are suitable for vertical runs within buildings, such as between floors or within riser shafts. They have fire-resistant jackets that restrict the spread of fire and do not emit excessive smoke or toxic gases when burning.

OFNP optical cables are used in plenum spaces, which are areas in buildings used for air circulation. Plenum spaces require optical cables with low smoke and flame propagation characteristics to prevent the spread of fire and the release of harmful fumes.