Preventive Maintenance Software

Bidhaa maelezo

Preventive maintenance is a very important part of equipment life cycle management. Using EAMic® preventive maintenance management software, maintenance team can always arrange the preventive maintenance work in advance, your assets will always receive the required maintenance care, and can avoid larger and higher problems, so as to save costs for the enterprise.

EAMic® Preventive Maintenance Software Help You

Get rid of paper and spreadsheets!

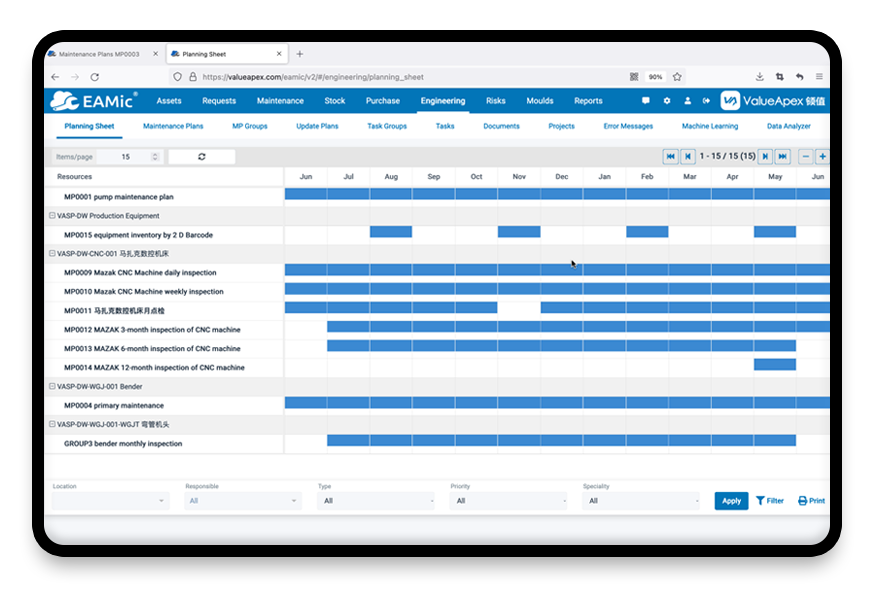

You can easily view, create, and edit maintenance plans, inspection plans, and annual overhaul plans for any group of equipment assets in your enterprise, and set the required resources and maintenance tasks, spare parts, employees, precautions and related documentation in the plan. Such as the frequency setting of regular replacement of spare parts, cycle, executive personnel, and the number of spare parts required.

EAMic® system will automatically generate or release PM work orders on a cycle or frequency and send mobile push notifications and tasks to technicians when assigned.

Maintenance Tasks

Using maintenance tasks management module, you can define the maintenance check content that needs to be done, and can create, modify, delete and add specific task items to the maintenance plan. Such as lubrication, maintenance and other tasks. Tasks can be managed by group and referenced in batches.

Update Plans

EAMic® system can batch modify some information in the maintenance plan, such as next_date, mp_name, type, priority, speciality, responsible (especially your employee left your company while he was responsible for many maintenance plans), Status, Duration, Period, Period_unit, Preparation, behavior, Cost_center, etc. Group maintenance plans can also be released in batch.

Maintenance Inspection Management

Inspection management is the core part of preventive maintenance management.

You can create inspection schedules for your enterprise's equipment groups, defining any required resources, task items, and related documentation. EAMic® system will automatically generate and release inspection work orders according to frequency or cycle.

You can also define the frequency and cycle of equipment inspection (day, week, month, year), and specify the personnel and task sequence. EAMic® will automatically release the corresponding inspection work order and send it to the calendar of the responsible person, mobile phone and email. Of course, according to the actual work needs, an inspection plan can also be manually released.

Maintenance technicians can complete PM work orders directly through the mobile APP, and perform inspections included in the maintenance plan. Management can access the status of any of the inspection points through the feedback logs uploaded to the EAMic® system.